Why Specify Classic Filters Coalescing Filter Elements?

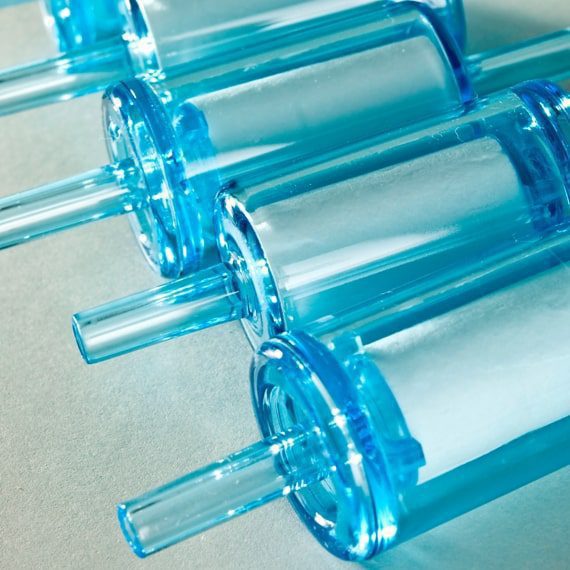

Fibrous filters, especially those manufactured by Classic Filters from borosilicate glass microfibers, are considered to be the most ideal filter media for the removal of liquid aerosols from gases – this is called coalescing filter.

Borosilicate Glass Microfibers for Coalescing Filters

Borosilicate glass microfibers are naturally hydrophobic and do not adsorb liquid – the aerosols and droplets stay in a spherical form rather than convert to a film on the fibres and this leads to very efficient coalescing. These types of filter elements offer the highest possible efficiency with a long service life and low cost.

Borosilicate glass microfibers are naturally hydrophobic and do not adsorb liquid – the aerosols and droplets stay in a spherical form rather than convert to a film on the fibres and this leads to very efficient coalescing. These types of filter elements offer the highest possible efficiency with a long service life and low cost.

As the filter media is self-supporting and self-sealing only the filter media is replaced – there are no end-caps and integral supports to dispose of.

Droplets and Aerosols are Captured by the Fibres

As droplets and aerosols are captured by the fibres of the inner layer of the filter element they run along the fibres and grow in size as the join together. As they pass through to the open drainage layer of the droplets naturally drains off to the outer diameter of the filter element. Surface tension of the liquid keeps it attached the element and they will fall by gravity to the bowl of the filter housing.

Sintered metal and plastic filter elements do not have the same natural filtration properties as fibrous filters and a film builds up on the inside these elements and increase the pressure drop. Sintered elements have about a three-times higher initial pressure drop versus microfiber because of the larger amount of material in the granular media. Or course, there are specific applications where sintered metal elements are a better solution and we offer them for those applications..

You can leave a comment below or

contact us if you have an application for a high efficiency coalescing filter by calling +44 (0)1634 724224, use the form on the right or send us an email to [email protected]