Filtering Samples with a High Level of Contaminate for a Petroleum Refinery

We were recently asked to solve a problem for a customer who saw high levels of pipe rouge and rust particles in his sample. The application was on white product blending.

So What What Was The Problem?

Unusually the problem was not so much to do with the filtration but with the stainless steel filter housings he was currently using from another supplier.

Although the housings are of similar design to our own standard housing design, his problem was that the particles of pipe rouge and rust were finding their way into the stainless steel filter housings head to bowl threads when the housings were serviced and could not be cleaned out. When the housings were re-assembled the bowls locked in the head and the housing had to be scrapped, this was happening at such short operation periods so a solution was urgently required.

The second point was the customer needed some kind of indication when the filter was blocking, so to avoid unnecessary disassembly.

So What Was Our Solution?

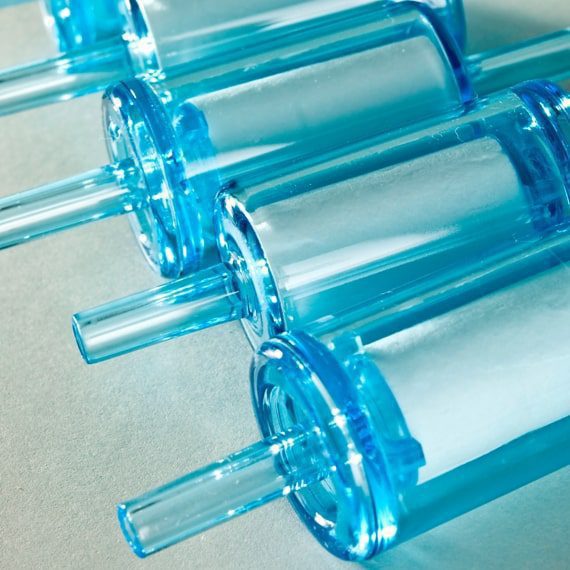

Our solution was to design a housing with the retaining thread isolated from the housing and changing from a head to bowl thread to a head bowl and collar design, this gave a much courser thread and was much easier to clean should any contaminate get into the thread. It also made the collar much easier to remove because of the spanner slots.

Next we designed the unit with one of our integral differential pressure indicators, to allow the customer visual indications of when the filter element is becoming clogged with contaminate.

Once again we have shown that our expertise and engineering knowledge can help customers in applications that present unusual problems. If you need some assistance to slove your problem please let us know.

You can leave a comment below or contact us by calling +44 (0)1634 724224, use the form on the right or send us an email to [email protected]