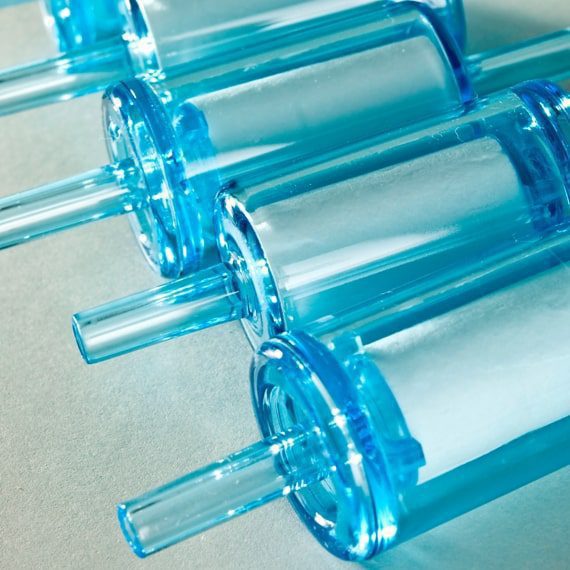

How to fit seals when installing a stainless steel filter element

We are often asked why seals are needed on our stainless steel filter elements. Because the 5-layer filter elements are sintered together it forms a rigid structure and unlike the disposable filter elements they cannot be sealed by axial compression.

The seals are available in a number of types and details can be found in the data sheet here. The most common types are a flat Viton seals and machined PTFE seals.

Flat Seals – Viton, EPDM and Nitrile

These flat seals must be located onto the filter housing head insert and element retainer as the filter element is installed. A little care must be taken to ensure the seal is in position correctly and it covers the end of the filter element. Then the element retainer is screwed onto the tie rod the seals are compressed to form a seal.

High Temperature and PTFE Seals

These seal types are machined form a solid bar stock into a L-shape section and locate on the ends of the filter element to help keep them in position as the filter element is installed.

For more information about our stainless steel filter elements please contact us by calling +44 (0)1634 724224 or send us an email to [email protected]