Is it possible to tell if a filter is blocked remotely?

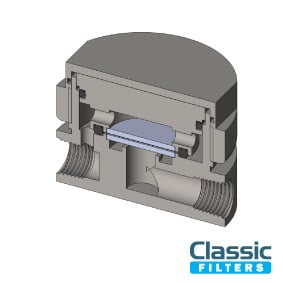

Does your application need a differential pressure indicator? Recently we were asked to solve a problem for a company operating unmanned oil production platforms. The way these platforms work mean that all of the systems are monitored remotely. Unless something out of the ordinary happens no-one visits the platforms until the regular service visit. However, one…